Welcome!

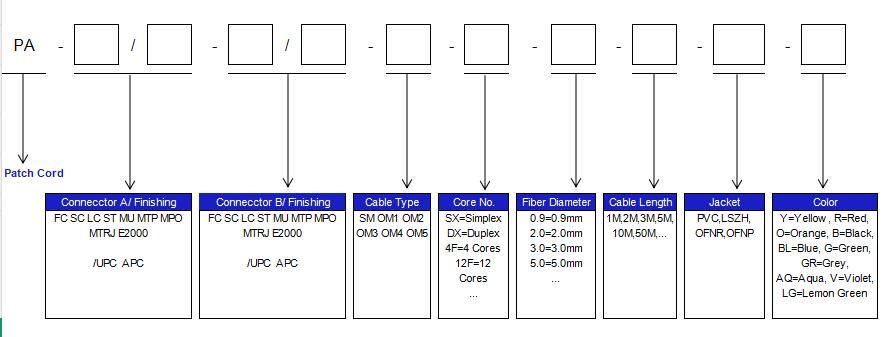

MPO-FC Breakout Cable, MPO Splitter Cable are designed for high density applications with require high performance and speedy installation, also called MPO Breakout Cable or MPO Fanout Cable, MPO FC cable, MPO-FC Harness Cables. The MPO breakout cables work from trunk backbone assemblies to fiber rack system in the high density backbone cabling. As mpo-12 breakout cable, mpo 12 breakout cable terminated with MPO/MTP connectors on one end and standard LC/FC/SC/ST/MTRJ connectors (generally MTP to FC) on the other end, these cable assemblies can meet a variety of fiber cabling requirements. Haiyu Optical MPO-FC breakout cable' fiber (core) counts are available in 8 to 144. We also provide Customized Service such as mpo to lc cable, mpo to sc breakout cable, mpo 12 cable, mpo 12 breakout cable, mpo to lc breakout cable, optional cable lengths to meet specific installation environments.

| Connector A | MTP | Connector B | FC UPC |

| Fiber Mode | MM OM3 | Wavelength | 850/1300nm |

| MTP Connector IL | 0.7dB Max (0.35dB Typ.) | FC Connector IL | ≤0.3dB |

| MTP Connector RL | SM≥55dB,MM≥25dB | FC Connector RL | SM≥55dB,MM≥35dB |

| Jacket OD | 3.0mm | fan-out Diameter | 0.9mm |

| Installation Tensile Load | 100 N | Long-Term Tensile Load | 50 N |

| Storage Temperature | -40°C to +85°C | Operating Temperature | -10°C to +70°C |

| Cable Jacket | LSZH | Fiber Count | 8/12Fibers |

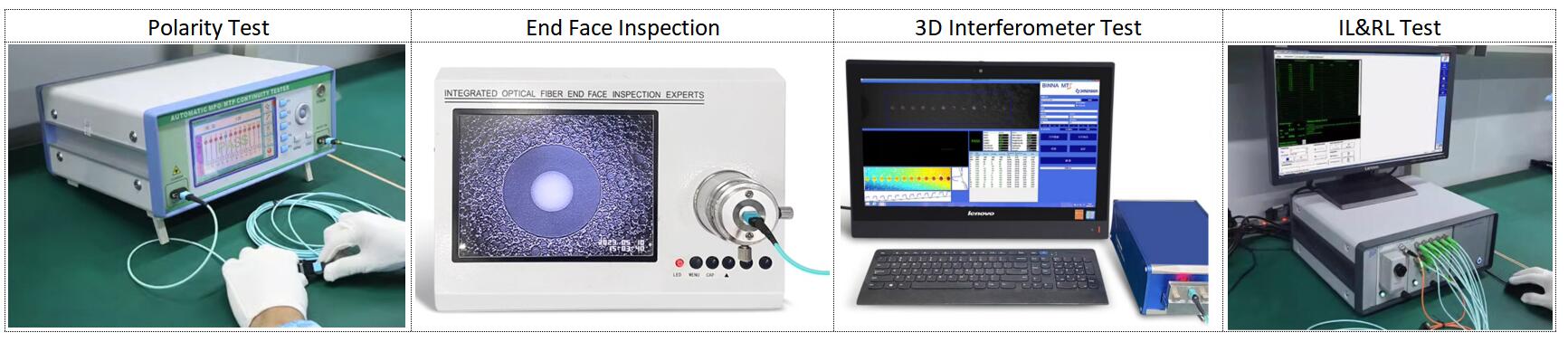

Haiyu Opticl has strictly test program to make sure every MPO/ MTP trunk cable 100% pass each test step. The Polarity test checking the polarity of each MPO MTP trunk cable. 3D interferometer provides verification of MTP/MPO polishing process, and making all parameters of the polished MT ferrule complies and exceeds industry standards. Clean optical connectors are paramount in providing a reliable, high-performance fiber optic infrastructure.

Quality and standards are the foundation of Haiyu Optical . We are dedicated to providing customers with the outstanding, standards-compliant products and services. Haiyu Optical has passed many quality system verifications, like ISO9001 and RoHS, established an internationally standardized quality assurance system and strictly implemented standardized management and control in the course of design, development, production, installation and service.