Welcome!

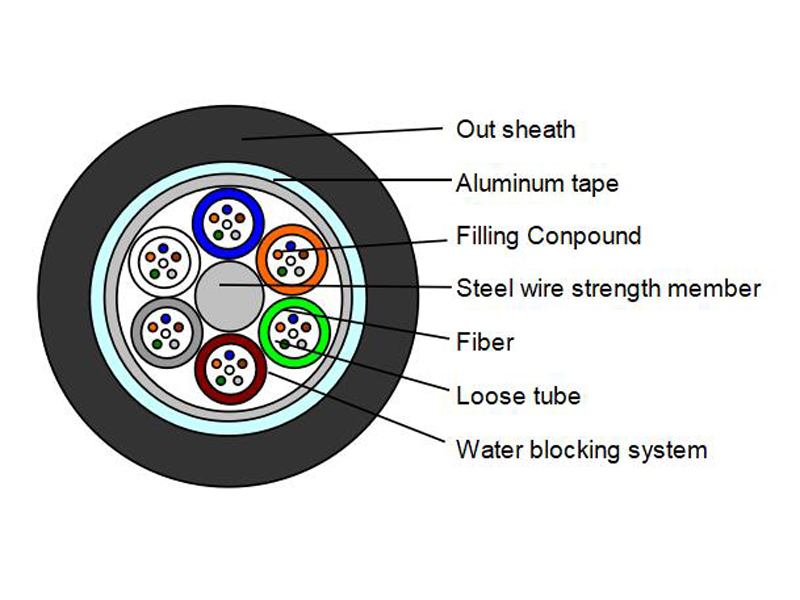

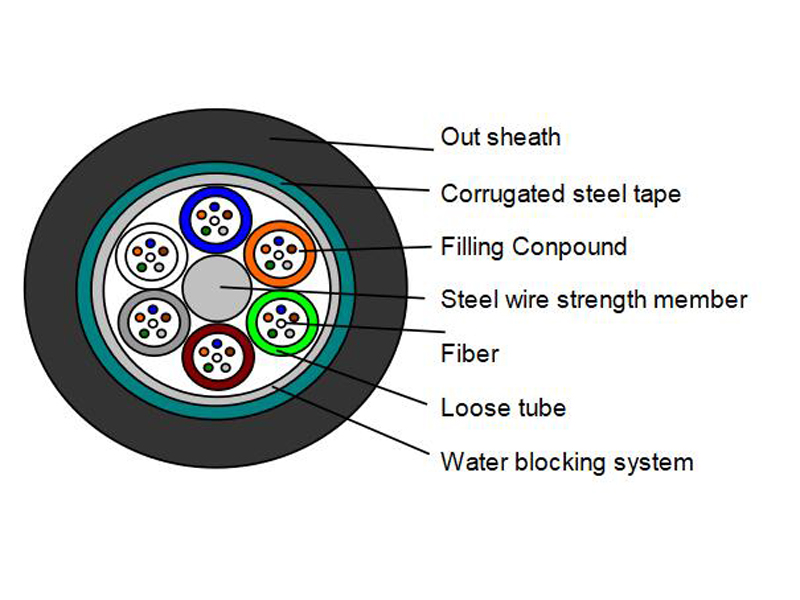

The coloring fiber are positioned in a central loose tube and Fillers are stranded around the metallic central strength member, it pass SZ into a compact, the PSP/APL is longitudinal covering, the cable is completed with PE sheath. In the loose tube, gap of the core is filled with the water-resistant filling compound.

Cable Count

Out sheath

Diameter

Weight

Minimum allowable Tensile Strength

(N)

minimum allowable Crush Load

(N/100mm)

Minimum Bending Radius

(MM)

Storage

temperature

(MM)

(KG)

short term

long term

short term

long term

short term

long term

(℃)

24

10.5

105.00

1500

600

1000

300

20D

10D

-40+60

36

10.5

105.00

1500

600

1000

300

20D

10D

-40+60

42

10.5

105.00

1500

600

1000

300

20D

10D

-40+60

48

12.0

150.00

1500

600

1000

300

20D

10D

-40+60

60

12.0

150.00

1500

600

1000

300

20D

10D

-40+60

72

12.0

150.00

1500

600

1000

300

20D

10D

-40+60

144

15.5

245.00

1500

600

1000

300

20D

10D

-40+60

288

21.5

415.00

1500

600

1000

300

20D

10D

-40+60

Steel wire strength.filler protect tube fiber.Aluminum tape armord.

Good ultra violet radiation resistant property.

Good moisture-resistance.